This bandsaw came from my grandads shed. Was completely falling apart and always tripped the breakers in the house. After 3yrs sitting in my sisters garage it was time to bring it back to life and put it back into service.

Starting Condition

The starting condition was fairly rough, everything had a layer of rust, sawdust or grime on it. The first step was to break it down into its parts, clean it all and remove all the old bad wiring and grease. The old base was wooden and full of bora holes ( kinda like termites ). The whole thing got chopped up for firewood as I wasn’t going to be using it and it wouldn’t find in the car.

New Base

I knew I wanted the new base to be stronger and house more than just the bandsaw. I figured out that a 1200mm x 600mm x 18mm sheet of plywood would be perfectly sized to hold the bandsaw, belt sander and keep my small air compressor underneath, the only catch was that the motor had to be flipped / reversed for it to fit. The fasten everything together I opted to T-Nuts and bolts as this also made it easier to disassemble and maintain.

I originally went with 2x swivel wheels and 2x lockable straight wheels but immediately realised it was a nightmare to move around so I went for 4x lockable swivel wheels instead.

Full Rewire

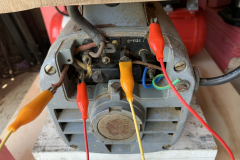

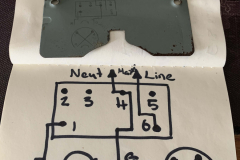

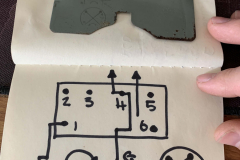

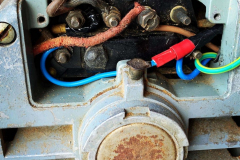

This was probably the hardest part of the whole project. To replace the wiring I ended up sacrificing old server power cables as they were long enough and heavy enough gauge. Wiring it was tricky but I eventually found that the wiring diagram was printed on the inside of the motor plate.

That wiring diagram also showed how to reverse wire it so the motor spun in the opposite direction which was great as I couldn’t find anything on the internet about this motor. As you can tell, the old wiring was frayed and corroded and in poor condition so it wasn’t a surprise that it use to blow all the fuses in the house.

New Blade

Getting a blade for this thing was much harder than expected. It turns out modern bandsaws use different blade sizes. The bandsaw has a fair amount of adjustment in it so I got the closest blade size of hardwood/soft metal I could find and made it fit.

I had to remove the spring in the top adjuster to allow it to lower enough and I had to relocate and drill a new mounting hole for the front cover bolt. Now this thing cuts like butter, I just need to adjust some of the tension to remove some of the vibration.

0 Comments